Laboratory Modular 12mm Twin Screw Extruder

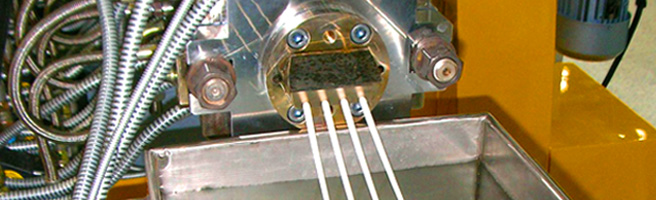

Labtech has launched a new 12mm co-rotating twin screw micro-compounder designed to be used with polymers in powder or micro pellets form with an approximate maximum granule diameter of 1.5mm. It is suitable for processing of minute polymer quantities for research applications but can also produce larger quantities having a maximum output of around 4 kg/hr.

The extruder is supplied complete with a stainless steel volumetric hopper feeder with a spiral type screw and with a stirring arm (agitator) above the feeding screw. The hopper feeder can optionally also be equipped with twin screws.

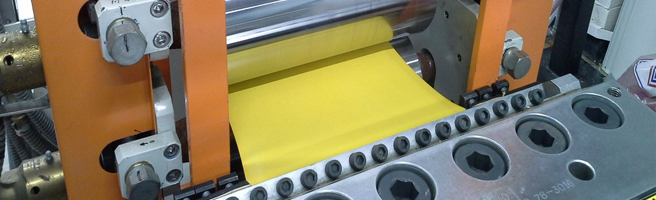

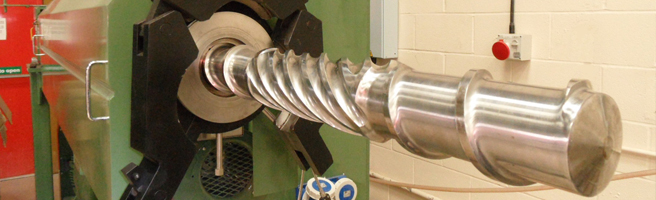

Inside the clam shell barrel are segmented screws where each segment can be placed anywhere on the hexagonal screw core shaft for optimum flexibility of screw configurations. The kneading elements are supplied as single sectors which can be placed against each other in various angles enabling numerous kneading and shearing functions.

Each barrel zone is equipped with both water cooling and electric cartridge heating which allows for complete process control at each zone of the barrel. Water cooling coupled with the high wattage heating enables fast temperature changes of each zone when changing processing conditions from one compound to another. The water cooling is achieved from fine channels inside each barrel module and regulated with individual solenoid valves from its designated temperature controller.

With an L/D extruder ratio of 36:1, the extruder is supplied as standard with an atmospheric venting zone on one of the barrel modules. This can optionally be equipped with a stainless steel vacuum housing, sight glass and manometer, connected to a dedicated extractor pump.

The extruder is designed with a sturdy sub-cabinet containing all electric and electronic components in compartments completely separated from the vacuum pump assembly. The control panel is mounted onto the body of the extruder and contains programmable pressure controller with digital indication of the screw tip pressure, digital RPM indicators for main screws speed and feeder screw speeds and clear warning lamps for any overloads or temperature problems.

Click here to visit the Labtech Engineering website for more information on twin screw extruders.

Millmerran Research and Manufacturing Ltd is the UK agent for the Labtech range of laboratory processing equipment. These machines are based on over 30 years experience and are built with a modern and pleasing design and a multitude of advanced features and safety standards in accordance with CE and other international norms, and every machine has the design, build quality and finish that have become recognised as the Labtech hallmark.